Matador Resources Company Provides Operational Update

This Smart News Release features multimedia. View the full release here: http://www.businesswire.com/news/home/20160718006271/en/

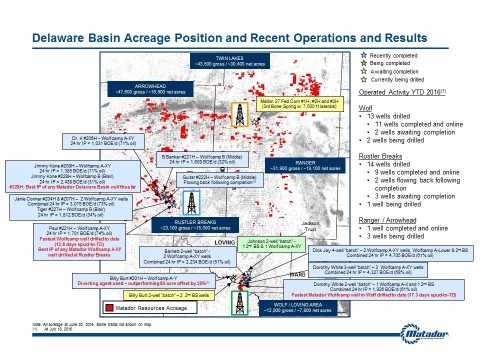

Map detailing Matador’s

Highlights of this release include the initial results from a number of

recent wells drilled and completed in Matador’s Rustler Breaks and Wolf

prospect areas in the

During the second quarter of 2016, Matador operated three drilling rigs

in the

Matador completed and placed on production a total of 22 gross (17.2

net) wells in the Rustler Breaks and Wolf prospect areas during the

second quarter of 2016, including 19 gross (16.4 net) operated and two

gross (0.3 net) non-operated horizontal wells. The Company also drilled

and completed one gross (0.5 net) vertical well at Rustler Breaks as

part of a successful acreage-holding operation with its working interest

partners. While the 19 gross operated horizontal completions were

somewhat higher than the 16 gross completions projected in Matador’s

first quarter earnings release on

Matador’s midstream operations continue to proceed as planned. As

previously reported, Matador is currently building a cryogenic natural

gas processing plant and the associated natural gas gathering system in

the Rustler Breaks prospect area to support its ongoing and future

development efforts there. The Rustler Breaks natural gas processing

plant is expected to have an inlet capacity of approximately 60 million

cubic feet of natural gas per day, and at

Rustler Breaks Prospect Area -

Initial Potential Test Results and Recovery Estimates

Matador operated two drilling rigs in its Rustler Breaks acreage during

the second quarter of 2016. As noted above, one of these rigs is

currently operating on the Company’s Ranger/Arrowhead prospect area, and

at

Matador is pleased to announce the 24-hour initial potential test

results from eight of these recent operated completions in its Rustler

Breaks prospect area in

The 24-hour initial potential test results from each well are summarized in the table below. The location of each well is shown on the attached map.

| Initial Potential | Completed | ||||||||||||||||

| Oil | Gas | BOE | % Oil | FCP(1) | Choke | Lateral Length | |||||||||||

| Well | Interval | (Bbl/d) | (MMcf/d) | (BOE/d) | (psi) | (inch.) | (feet) | ||||||||||

| Paul 25-24S-28E RB #221H | Wolfcamp A-XY | 1,253 | 2.7 | 1,701 | 74% | 2,425 | 34/64" | 4,455 | |||||||||

| Janie Conner 13-24S-28E RB #204H | Wolfcamp A-XY | 1,146 | 2.4 | 1,550 | 74% | 2,380 | 34/64" | 4,455 | |||||||||

| Janie Conner 13-24S-28E RB #207H | Wolfcamp A-XY | 1,094 | 2.6 | 1,525 | 72% | 2,130 | 34/64" | 4,455 | |||||||||

| Jimmy Kone 05-24S-28E RB #208H | Wolfcamp A-XY | 982 | 2.4 | 1,385 | 71% | 2,100 | 34/64" | 4,586 | |||||||||

| Dr. K 24-23S-27E RB #206H | Wolfcamp A-XY | 732 | 1.8 | 1,031 | 71% | 1,500 | 34/64" | 4,324 | |||||||||

| B. Banker 33-23S-28E RB #221H | Wolfcamp B (Middle) | 515 | 6.6 | 1,608 | 32% | 2,700 | 36/64" | 4,251 | |||||||||

| Jimmy Kone 05-24S-28E RB #228H | Wolfcamp B (Blair) | 751 | 10.1 | 2,438 | 31% | 2,975 | 36/64" | 4,586 | |||||||||

| Tiger 14-24S-28E RB #227H | Wolfcamp B (Blair) | 623 | 7.1 | 1,812 | 34% | 2,770 | 36/64" | 4,586 | |||||||||

| (1) Flowing casing pressure. | |||||||||||||||||

Matador continues to be very pleased and encouraged with the well

results in its Rustler Breaks prospect area. The five Wolfcamp A-XY

wells reported in the table above are consistent with or better than the

best Wolfcamp A-XY wells drilled by Matador in this prospect area to

date. The Paul #221H well tested at the highest 24-hour initial

potential of any Wolfcamp A-XY well drilled by Matador at Rustler

Breaks, and early performance from this well indicates that it may be

the best Wolfcamp A-XY well drilled to date at Rustler Breaks with an

initial estimated ultimate recovery above 900,000 BOE. Likewise, early

performance from most of these Wolfcamp A-XY wells is tracking near or

above Matador’s 800,000 BOE Wolfcamp A-XY type curve for the Rustler

Breaks area. Early results from several of these recent Wolfcamp A-XY

completions appear comparable to those of Matador’s earliest Wolfcamp

A-XY tests in the Rustler Breaks prospect area—the Guitar 10-24S-28E RB

#202H (Guitar #202H) and the Tiger 14-24S-28E RB #204H (Tiger #204H)

wells. As of

Matador is also very pleased to report the results of its first two

wells drilled in the deepest bench of the Wolfcamp B (

The 24-hour initial potential flow rates from the Jimmy Kone #228H and

the Tiger #227H wells are the two highest 24-hour test results reported

by Matador in the

Operational Efficiencies and Improved Drilling Times

In addition to these encouraging well results, Matador’s operational

efficiencies continue to improve at Rustler Breaks and throughout its

These same drilling efficiencies are also reflected in the Wolfcamp B wells. Through the first half of 2016, Matador has further reduced its average drilling time in the Wolfcamp B to 21.7 days from spud to total depth, as compared to an average of 41.3 days in late 2014 and 32.0 days in 2015, representing decreased drilling times of 47% and 32%, respectively. Further, the Company’s fastest-drilled Wolfcamp B well, the B. Banker #221H well, was drilled in 17.5 days from spud to a total depth of 15,151 feet, a decrease of 58% from the average drilling time in late 2014. This 17.5 days is likewise faster than Matador’s 2016 Wolfcamp B drilling objective of 18 days from spud to total depth, which it had targeted to achieve by year-end 2016. Matador continues to deliver faster drilling times as a result of its increased knowledge of the geology and its experience with drilling in the Rustler Breaks area, as well as improvements in drilling the curve between the vertical and horizontal portions of these wells and continued applications of improved drill bit and bottomhole assembly technologies.

Well Cost Improvements

Due in part to these improvements in drilling times, the costs

associated with these recent Wolfcamp A-XY wells continued to decline

and were among the lowest achieved by Matador to date. The costs to

drill, complete and equip the two

Wolf Prospect Area –

Initial Potential Test Results and Recovery Estimates

Matador operated one drilling rig in its Wolf prospect area during the

second quarter of 2016. Matador completed and placed on production 10

gross (8.8 net) operated horizontal wells at Wolf during the second

quarter, including five Wolfcamp A-X, three Wolfcamp A-Y, one Wolfcamp

A-Lower and one Second Bone Spring completions. Results from six of

these second quarter completions in the Wolf prospect area, including

three Dick Jay wells and three Dorothy White wells, were provided with

Matador’s

Matador is pleased to announce the 24-hour initial potential test results from its four most recent completions in the Wolf prospect area. Two of these wells were completed in the Wolfcamp A-X interval, one was completed in the Wolfcamp A-Y interval and the fourth was a Second Bone Spring completion. Each of these wells had a completed lateral length between approximately 4,400 and 4,800 feet.

The 24-hour initial potential test results from each well are summarized in the table below. The location of each well is highlighted on the attached map.

| Initial Potential | Completed | ||||||||||||||||

| Oil | Gas | BOE | % Oil | FCP(1) | Choke | Lateral Length | |||||||||||

| Well | Interval | (Bbl/d) | (MMcf/d) | (BOE/d) | (psi) | (inch.) | (feet) | ||||||||||

| Dorothy White 82-TTT-B33 WF #123H | Second Bone Spring | 526 | 2.0 | 866 | 61% | 1,660 | 34/64" | 4,658 | |||||||||

| Dorothy White 82-TTT-B33 WF #203H | Wolfcamp A-X | 656 | 2.4 | 1,060 | 62% | 2,750 | 28/64" | 4,370 | |||||||||

| Barnett 90-TTT-B01 WF #203H | Wolfcamp A-X | 510 | 2.9 | 994 | 51% | 2,950 | 30/64" | 4,796 | |||||||||

| Barnett 90-TTT-B01 WF #204H | Wolfcamp A-Y | 632 | 3.6 | 1,240 | 51% | 3,120 | 30/64" | 4,825 | |||||||||

| (1) Flowing casing pressure. | |||||||||||||||||

The 24-hour initial potential test results from these most recent

Wolfcamp A-X and A-Y completions were largely as expected and consistent

with other Wolfcamp A-X and A-Y wells completed in the Dorothy White and

Barnett portions of Matador’s Wolf prospect area. In addition, Matador

is particularly pleased and encouraged with the test results observed

from the Dorothy White #123H well, a Second Bone Spring completion. Both

this well and the Dick Jay 92-TTT-B01 WF #124H (Dick Jay #124H) well,

also a Second Bone Spring completion, reported in the Company’s

Matador attributes the improvement in well performance and estimated

ultimate recovery from both the Dick Jay #124H and Dorothy White #123H

wells to the increased stimulation treatments pumped on both wells. Both

wells were completed with approximately 40 barrels of fluid and 2,000

pounds of 20/40 sand per foot of completed lateral, as compared to 20

barrels of fluid and about 1,300 pounds of 30/50 sand per foot of

lateral in Matador’s first Second Bone Spring test in the Wolf area. As

noted in its previous operational update, given the success of the Dick

Jay #124H and Dorothy White #123H tests in the Second Bone Spring,

Matador plans to work additional Second Bone Spring tests into its

drilling schedule at Wolf during 2016, including three in the third

quarter of 2016 on both its

Operational Efficiencies and Improved Drilling Times

Operational efficiencies continue to improve in the Wolf area as well. Through the first half of 2016, Matador has further reduced its average drilling time in the Wolfcamp A-X and A-Y to 18.3 days from spud to total depth, as compared to an average of 43.0 days in 2014 and 24.2 days in 2015, representing decreased drilling times of 57% and 24%, respectively. Matador’s fastest-drilled Wolfcamp A well, the Dorothy White #203H well, was drilled in 17.3 days from spud to a total depth of 15,550 feet, a decrease of 60% from the 2014 average drilling time. The average drilling time in the Wolfcamp A at Wolf in 2016 of 18.3 days is already approaching Matador’s Wolfcamp A drilling objective of 18 days from spud to total depth that Matador has targeted to achieve by year-end 2016, and the 17.3 days achieved on the Dorothy White #203H well is faster than Matador’s 2016 Wolfcamp A year-end target at Wolf.

Similar drilling efficiencies are also being achieved in the Second Bone

Spring wells. Matador has reduced its drilling time in the Second Bone

Spring from 21.8 days on its first well drilled in the Second Bone

Spring in 2015 to an average drilling time of 12.6 days in 2016, a

decrease of 42%. Both the Dick Jay #124H and the Dorothy White #123H

wells were drilled in approximately 12.6 days from spud to total depth,

with both drilling times being faster than Matador’s 2016 year-end

drilling target of 13 days for its Second Bone Spring wells. In both the

Dick Jay #124H and Dorothy White #123H wells, Matador’s drilling

engineers were also able to eliminate a second intermediate casing

string typically used when drilling the Second Bone Spring in this area.

Not only did eliminating this casing string save approximately

Well costs associated with recent Wolfcamp A-X and A-Y wells drilled and

completed in the Wolf area also continue to decline. Costs to drill,

complete and equip recent Wolfcamp A wells have ranged between

Ranger Prospect Area –

Matador did not drill or complete any wells in either its Ranger or

Arrowhead prospect areas during the second quarter. As noted earlier in

this release, the Company has moved one of its operated drilling rigs

from Rustler Breaks to the northwest portion of its Ranger prospect

area. This rig has just begun drilling a three-well program on Matador’s

Mallon leasehold. All three wells will be Third Bone Spring tests, and

all will be approximately 7,500-foot laterals. These will also be the

first three operated wells that Matador has drilled on the acreage

acquired in its merger with

During 2016 and again during the second quarter, Matador has tested and studied a variety of different stimulation designs and other technologies in an attempt to improve well recoveries, completion costs or both. In the following discussion, the Company provides some preliminary thoughts on the results of certain of these design changes and stimulation technologies.

Increased Proppant Concentrations – Up to 3,000 pounds per foot in Wolfcamp completions at Wolf and Rustler Breaks: As stimulation costs have decreased in 2016, Matador has taken the opportunity to test increased proppant concentrations in a number of its recent Wolfcamp A and B completions in both the Wolf and Rustler Breaks prospect areas. All Wolfcamp A-XY wells completed and placed on production at Rustler Breaks during the second quarter of 2016 were stimulated with approximately 40 barrels of fluid and 3,000 pounds of 30/50 sand per foot of completed lateral – the Company’s Generation 3 Wolfcamp treatment design. Likewise, three of the wells completed and stimulated in the second quarter of 2016 in the Wolf prospect area also tested this Generation 3 Wolfcamp treatment design. Prior to this, most of the Company’s Wolfcamp A and B completions used approximately 30 to 40 barrels of fluid and 2,000 pounds of 30/50 sand per foot of completed lateral.

Matador continues to be very pleased with the initial performance of its Wolfcamp A and B wells at both Rustler Breaks and Wolf, but the Company has yet to form any final conclusions about the advantage of using proppant concentrations up to 3,000 pounds per foot in the Wolfcamp. One recent comparison does suggest increased early well performance may be a result of the higher proppant concentrations. At Wolf, two offsetting wells were drilled and completed on Matador’s Dorothy White leasehold. One, the Dorothy White 82-TTT-B33 WF #202H (Dorothy White #202H) well, was completed with approximately 3,000 pounds of 30/50 sand per lateral foot and the other, the Dorothy White 82-TTT-B33 WF #204H (Dorothy White #204H) well, was completed with approximately 2,000 pounds of 30/50 sand per lateral foot. Both wells are Wolfcamp A-X completions. In this instance, the Dorothy White #202H well (3,000 pounds per foot) has outperformed the Dorothy White #204H well (2,000 pounds per foot) by about 20% in the first 75 days of production from both wells, as normalized to equal lateral lengths.

The Company will continue to monitor longer-term production results from

wells treated with this Generation 3 stimulation design to assess its

impact on well performance and estimated ultimate recoveries. Should the

lower proppant concentrations prove as effective as the higher proppant

volumes, stimulation costs in future wells could be reduced even further

by as much as

Increased Proppant Concentrations – Up to 2,000 pounds per foot in Second Bone Spring completions at Wolf: As noted above, Matador has increased the stimulation treatment pumped on its Second Bone Spring completions at its Wolf prospect area in recent wells. This Generation 3 Second Bone Spring completion includes 40 barrels of fluid and 2,000 pounds of 20/40 sand per foot of lateral, as compared to 20 barrels of fluid and about 1,300 pounds of 30/50 sand per foot of lateral on previous Second Bone Spring completions. This increase in both fluid volume and proppant concentration has led to significantly improved well performance and estimated ultimate recoveries from both the Dick Jay #124H and Dorothy White #123H Second Bone Spring completions in the Wolf prospect area during 2016. Matador will continue to use this Generation 3 stimulation design in future Second Bone Spring completions in the Wolf prospect area as part of its continuing effort to optimize these Second Bone Spring completions.

Use of Diverting Agents at Wolf: Matador has pumped various diverting agents in several of its recent stimulation treatments in its Wolf prospect area in an effort to ensure as many perforation clusters as possible are taking fluid during a particular fracturing stage. These diverting agents are biodegradable materials that are added to the stimulation fluid at the midpoint of each stage. Designed to temporarily plug off those perforation clusters that are taking most of the fracturing fluid and proppant initially in a given treatment stage, these materials “divert” the treatment to those perforation clusters that are not being treated, thereby opening and propping additional fractures. These diverting agents then degrade or dissolve from all perforations soon after the treatment stage is completed allowing for unrestricted flow back of the hydrocarbons and treatment fluids.

Matador continues to see clear mechanical evidence that the diverting

agents are helping to open additional perforations and to stimulate

additional reservoir rock during pumping operations and believes that

these diverting agents are contributing to better well results. The best

example of this improved well performance continues to be the Company’s

Billy Burt 90-TTT-B33 WF #201H well (Billy Burt #201H), where it used a

diverting agent as part of the fracture treatment for the first time in

Matador expects to continue using diverting agents in its Wolfcamp fracture treatments in the Wolf prospect area and also plans to begin pumping diverting agents in its upcoming Wolfcamp fracture treatments at Rustler Breaks as well.

Use of Dissolvable Balls and Dissolvable Plugs at Wolf and Rustler

Breaks: Matador has tested flow-through plugs with dissolvable balls

on its two most recent Second Bone Spring completions in the Wolf

prospect area. This technology performed very well on both wells,

eliminating the need for the plugs to be drilled out following fracture

stimulation operations and saving approximately

Matador has recently used fully dissolvable fracturing plug technology for the first time in one of its Wolfcamp B wells at Rustler Breaks. As this well is cleaning up following the fracture treatment, there are insufficient results at this time to draw conclusions as to the effectiveness of the dissolvable plugs, but the Company will continue to monitor and evaluate this new technology.

Use of Recycled Water in Stimulation Treatments at Wolf: As noted in prior releases, Matador continues to use recycled produced water in the stimulation of its newly drilled wells in the Wolf prospect area. Recycled produced water has made up between 70% and 100% of the total water volumes used on the eleven wells drilled and completed in the Wolf prospect area thus far in 2016. Using recycled water saves the Company on costs to source fresh water, as well as the disposal costs associated with produced water, in addition to conserving fresh water for other uses in the Wolf area.

Given the success of using recycled water for stimulation treatments in the Wolf prospect area, Matador has recently initiated recycling operations at Rustler Breaks in order to begin using recycled water for stimulation treatments there as well in the near future.

Second Quarter 2016 Earnings Release and Earnings Conference Call

Matador plans to announce its second quarter 2016 operational and

financial results after the close of trading on

To access the live conference call, domestic participants should dial

(855) 875-8781 and international participants should dial (720)

634-2925. The conference ID and passcode is 47930778. The live

conference call will also be available through the Company’s website at www.matadorresources.com

on the Presentations & Webcasts page under the Investors tab. The replay

for the event will be available on the Company’s website at www.matadorresources.com

on the Presentations & Webcasts page under the Investors tab through

About

Matador is an independent energy company engaged in the exploration,

development, production and acquisition of oil and natural gas resources

in

For more information, visit

Forward-Looking Statements

This press release includes “forward-looking statements” within the

meaning of Section 27A of the Securities Act of 1933, as amended, and

Section 21E of the Securities Exchange Act of 1934, as amended.

“Forward-looking statements” are statements related to future, not past,

events. Forward-looking statements are based on current expectations and

include any statement that does not directly relate to a current or

historical fact. In this context, forward-looking statements often

address expected future business and financial performance, and often

contain words such as “could,” “believe,” “would,” “anticipate,”

“intend,” “estimate,” “expect,” “may,” “should,” “continue,” “plan,”

“predict,” “potential,” “project,” “hypothetical,” “forecasted” and

similar expressions that are intended to identify forward-looking

statements, although not all forward-looking statements contain such

identifying words. Actual results and future events could differ

materially from those anticipated in such statements, and such

forward-looking statements may not prove to be accurate. These

forward-looking statements involve certain risks and uncertainties,

including, but not limited to, the following risks related to financial

and operational performance: general economic conditions; the Company’s

ability to execute its business plan, including whether its drilling

program is successful; changes in oil, natural gas and natural gas

liquids prices and the demand for oil, natural gas and natural gas

liquids; its ability to replace reserves and efficiently develop current

reserves; costs of operations; delays and other difficulties related to

producing oil, natural gas and natural gas liquids; its ability to

integrate acquisitions, including the merger with

View source version on businesswire.com: http://www.businesswire.com/news/home/20160718006271/en/

Source:

Matador Resources Company

Mac Schmitz, 972-371-5225

Capital

Markets Coordinator

mschmitz@matadorresources.com